E-mail: chenwei@czcwjx.com

Pellets suitable for the entrance: Anti-cut material inlet shape design, even if the upstream material can be safely start full.

An exhaust port: [selection of positive pressure conveying] When the impeller rotating high-pressure gas out through the exhaust port to the exhaust, charging efficiency can be improved.

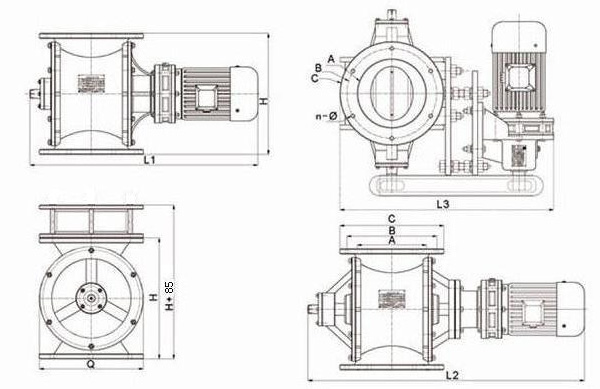

Common type: compact, small footprint

Bearing External: to prevent dust intrusion bearings, increasing device adapt to the temperature range of use.

Drive: Chain drive / motor directly connected to the drive.

Engine: cycloid reducer, Y series motor [can specify the power demand side preparation].

Material: cast iron / steel / 201 stainless steel / 304L Stainless Steel / 316L stainless steel / titanium alloy.

| Model | A | B | C | H | Q | L1 (Inside) | L2 (Outside) | L3 (Chain) | n-Ф | Working temperature ℃ | Speed Turn / Points | Motor Power KW |

| 2L | 150 | 200 | 240 | 240 | 180 | 580 | 730 | 560 | 8-Ф13 | Built-in≤80 External≤300 | 0.75 | |

| 3L | 150 | 200 | 240 | 300 | 260 | 620 | 780 | 610 | 0.75 | |||

| 4L | 180 | 240 | 280 | 280 | 260 | 640 | 800 | 630 | 0.75 | |||

| 6L | 200 | 260 | 300 | 300 | 300 | 680 | 820 | 650 | 1.1 | |||

| 8L | 220 | 280 | 320 | 320 | 320 | 710 | 850 | 690 | 1.1 | |||

| 10L | 240 | 300 | 340 | 340 | 340 | 730 | 900 | 710 | 1.1-1.5 | |||

| 12L | 260 | 320 | 360 | 360 | 360 | 780 | 950 | 730 | 1.1-1.5 | |||

| 16L | 300 | 360 | 400 | 400 | 380 | 820 | 1000 | 750 | 1.5 | |||

| 26L | 400 | 460 | 500 | 555 | 450 | 870 | 1200 | 770 | 12-Ф17 | 2.2-3 | ||

| 40L | 500 | 558 | 620 | 620 | 480 | 910 | 1300 | 880 | 3-4 | |||

| 80L | 550 | 620 | 670 | 680 | 500 | 1200 | 1350 | 950 | 4-5.5 | |||

| 150L | 600 | 670 | 720 | 740 | 580 | 1400 | 1600 | 1100 | 5.5-7.5 |