B, X series cycloid reducer

Cycloid reducer is a cycloid use meshing planetary transmission principle design and manufacture of gear. Its advanced design, new structure, with a carrying capacity, high transmission efficiency, long life, compact structure, smooth operation, easy maintenance and other significant advantages for metallurgy, mining, lifting, transportation, construction, chemical, light industry, textile, printing and dyeing, food, machinery and other departments to do a variety of transmission machinery in the reduction mechanism.

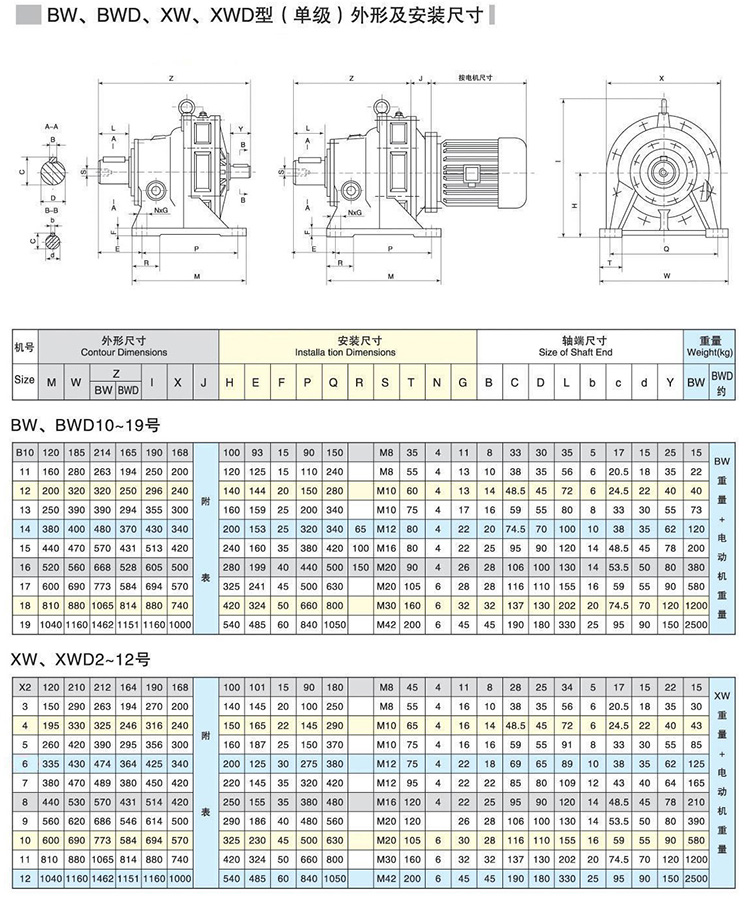

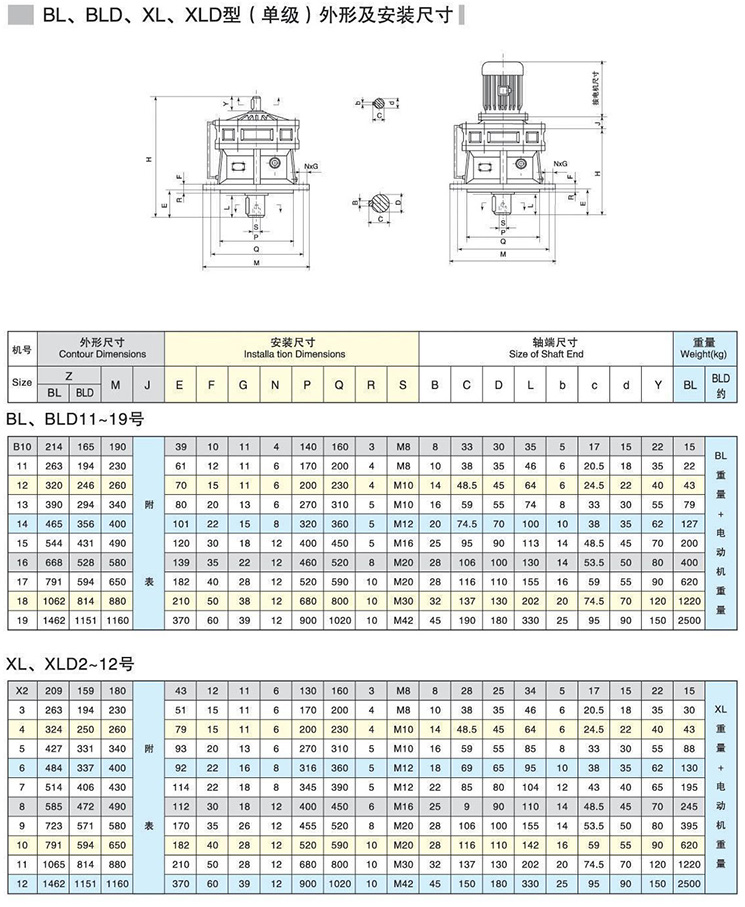

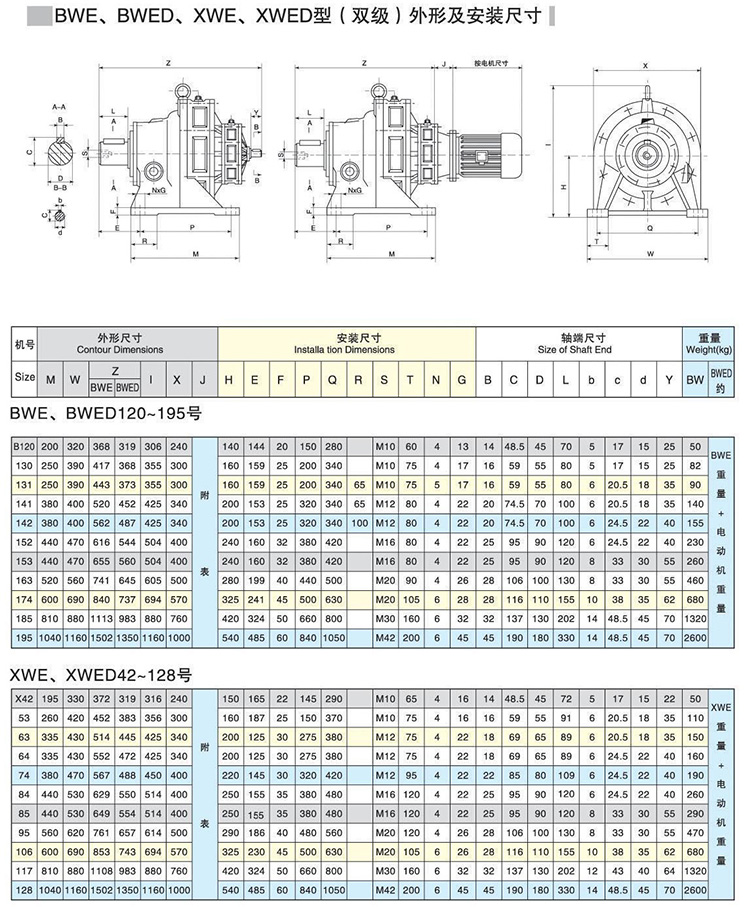

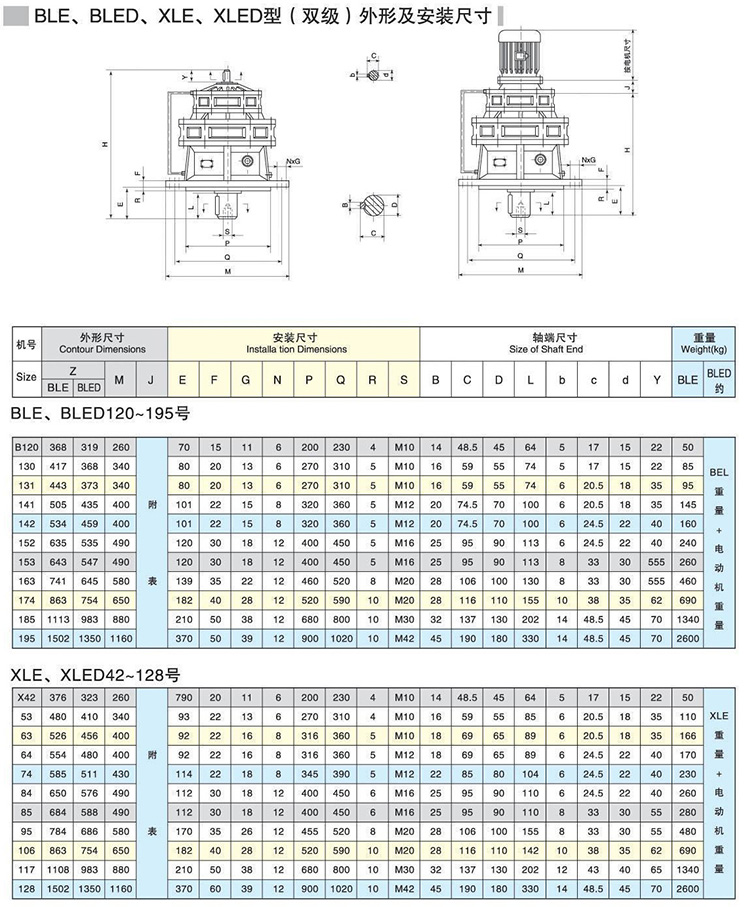

I produced the BW (Y), a single-stage transmission XW (Y) and the two-stage type transmission and BL (Y), XL (Y) type of single-stage and two-stage transmission, perform Q / 320801, JA010-2002 "pendulum line pin wheel reducer "corporate standards, their working conditions should meet the following requirements:

a、the input shaft is not greater than the maximum speed 1500r / min.

b、Axis type reducer working environment temperature -40 ℃~ + 40 ℃, in turn fixed under rated load, slow down the oil tank temperature does not exceed 45 ℃, the highest oil temperature does not exceed 85 ℃.

c、Direct-coupled gear motor power supply is rated at 380V, rated frequency of 50Hz, when the altitude does not exceed 1000m allow working environment temperature -10 ℃~ + 40 ℃; when allowed to work more than 1000m above sea level Ambient temperature -10 ℃~ + 35 ℃. At rated speed and load, speed reducer in the workplace under the above two sump temperature exceeds 45 ℃, the maximum temperature should not exceed 85 ℃and 80 ℃, respectively.

d、Reducer apply to forward and reverse movement.

Use and maintenance

Use:

a)The machine is suitable for continuous duty, allowing the reverse, reverse operation.

b)When the output shaft and the input shaft and the other parts fit, it does not allow direct hammer to put damage. The output shaft installation of couplings should use the outer end of the output shaft screw depressed.

c)Key output shaft and the input shaft on the application in the normal flat key type size (GB1096-79) provisions choose.

d)Applicable coupling and working machine and motor coupling should make concentric axis; installation error should not exceed reducer usedCoupling tolerance values.

e)After installing gear turned by hand should be flexible.

f)Horizontal axis type reducer output shaft axis generally in a horizontal position; when using the tilt axis elevation must not exceed 15 °(toward the lower output shaft).

g)Vertical gearbox output shaft extension should end vertically downward use.

h)After installing the gear unit, must be carried out before the official use of commissioning; sub air under normal circumstances, and then gradually loaded using running.

i)The impact load is large, frequent starting time to stand with the other base shall, with positioning pins, or use hydraulic couplings.

Maintenance:

a)Store front gear not in use installed in a dry room, should be stored in open storage box easily make rain infiltration bubble somewhere and have a water-resistant measures.

b)Reducer should be required to carry out the oil change, such as the emergence of oil-degrading phenomenon should be replaced immediately.

Reducer should be used to regularly check usage, as a loosening bolts, abnormal vibration during operation, shock, noise and so on, should immediately stop inspection, and other anomalies discharged before use.